> Business > Display Equipment

> Business > Display Equipment

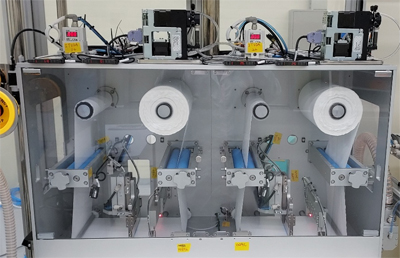

It cleans the remaining dust after removing film / before POL attachment & lamination process.

: It cleans Cell for 4”, 7” or medium & large size of Mobile Display Line through Cassette Method. It is capable for Loader & Unloader structure of Cassette to Cassette or Try to Try method.

It cleans the glass board in the cassette method.

It cleans the floating particles before attaching OLED POL.

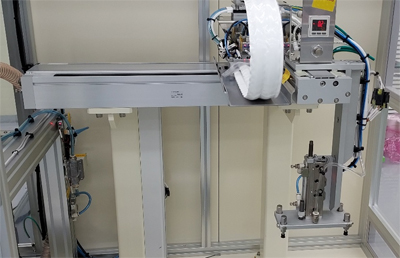

It is a high performance equipment of the optimized design for cleaning particles and stain before WFA process.

High performance equipment of the design for cleaning particles and floating dust on Tray as well as drying and inspection.

High performance utility equipment of the design for optimizing the Tray cleaning process as well as minimizing the total cost.

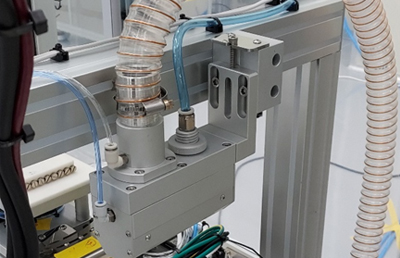

Loading Stage Unit

Loading Stage Unit USC Unit

USC Unit Cleaning Unit

Cleaning Unit Unloader T/R Unit

Unloader T/R UnitIt cleans the floating dust and remaining particles, stain on Panel.

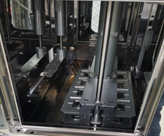

It cleans the remaining OCA on front side of Panel for its rework after separating Cover Glass and Panel.

It cleans CRD and ACF for FPC rework.

It cleans the remaining OCA on the back side of Cover Glass for its rework.

Dipping Unit

Dipping Unit Brush Unit

Brush Unit PPC Unit

PPC Unit Align Unit

Align Unit Cleaning back side

Cleaning back side Cleaning front side

Cleaning front sideIt cleans Cover Glass and the remaining OCA on the back side of Cover Glass for its rework.